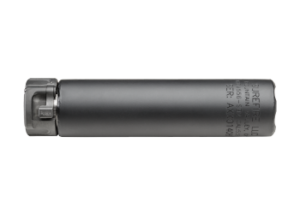

In 2002 SureFire® created its suppressor division to redefine suppressor technology, materials, and construction. Starting with the finest U.S. mill-certified high-temperature alloys available, SureFire® engineered the most advanced and fail-safe suppressor baffle system ever devised. It met all their ambitious criteria for sound, flash, and dust signature reduction while remaining compact in size, lightweight, and supremely durable. They torture-tested every design relentlessly to ensure that it met their goals while consistently producing a sub-1 MOA shift in point of impact compared to the same weapon unsuppressed, regardless of the number of attach-detach cycles. Their patented front plate design virtually eliminated the first-round flash signature. Their patented Fast-Attach® mounting system provided a rock-solid interface with the weapon and fast and easy detachment after extensive firing. The philosophy at SureFire® has always been that durability, signature reduction, accuracy, repeatability, and sound suppression are the most important factors to consider when evaluating a suppressor design for combat or duty use.

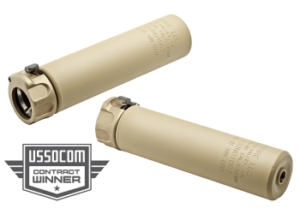

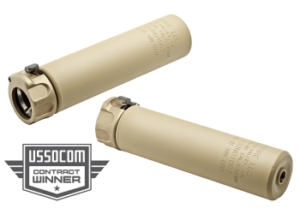

Once they were satisfied, they had met their own goals; they summated their suppressors for the SOCOM suppressor solicitation. The SOCOM suppressor solicitation was the most demanding suppressor trial ever performed by the U.S. Military. In 2011 SureFire® was awarded the SOCOM Suppressor contract for $23.3 million.

In 2017 they were awarded another $10 million contract.

This contract is the second award based on the most rigorous and extensive suppressor selection in USSOCOM history.

In 2019 The military established NSN’s for the SOCOM556-RC2.

SureFire® makes SOCOM model suppressors for weapons systems from 5.56 to .50 Caliber weapons.

There are four SOCOM series models in 5.56 caliber; SB2, RC2, the Mini2, and MG. All of these come in both black and dark earth. All of these suppressors except the Mini2 have NSN’s assigned to them.

There is additionally four SOCOM series models in 7.62 caliber; SB2, RC2, TI, and MG. The MG model has an assigned NSN.

The SOCOM300-SPS was designed for the 300 Blackout, but works for all calibers from 5.56 thru 300WM.

The SOCOM338 TI is 9.9 inches long and weighs 22.0 OZ, but it is a beast at handling the 338 Lapua and has an assigned NSN.

The SOCOM 50 SPS at 14.4 inches long and 86 oz is a large suppressor to be sure, but it also accommodates the large 50 caliber round. The SOCOM 50 SPS delivers up to a 99% reduction in flash to conceal the shooter’s location.

The newest kids on the block are the SOCOM65-RC2 and the SOCOM65-TI. These suppressors are for 6.5mm, 6mm, .260 calibers. The SOCOM65-RC2 is the 6.5 mm/6 mm/.260-caliber version of the U.S. Special Operations Command selected suppressor for the Mk13 Sniper Rifle.

All SureFire® suppressors are designed and built in the USA.

SOCOM65-RC2 SUPPRESSOR

- The combat-grade suppressor for 6.5 Creedmoor, 6 mm and .260 caliber rifles

- Full-auto reliability

- Reduces sound at shooter’s ear to 130 dB, cuts visible muzzle flash by 98%

Get The Most Out Of Your Creedmoor. Why would you accept less than the best suppressor for your 6.5 mm Creedmoor, .260 caliber, or 6 mm semi-automatic rifle? The SOCOM260-RC2 utilizes the same technically advanced, no-compromise design and engineering that earned the SOCOM556-RC suppressor a victory in the harshest, most demanding suppressor trials in USSOCOM history. Using the latest manufacturing techniques and materials, a class-leading suppressor delivers the utmost in sound attenuation and flash and dust signature reduction. CNC laser-welded Inconel alloy and stainless steel materials provide uncompromising durability. Inside, the technically superior internal baffling reduces backpressure and sound to match supreme accuracy with extreme quiet. It makes your 6.5 Creedmoor a 10 in the stealth department.

SOCOM65-TI SUPPRESSOR

- The ideal titanium suppressor available for 6 mm, 6.5 mm and .260 caliber bolt-action rifles

- The lightest SureFire® suppressor; minimal effect on weapon handling

- Optimal bore concentricity and suppressor alignment deliver extremely consistent accuracy.

Send It. The revolutionary SureFire® SOCOM65-Ti is the lightest rifle-mount suppressor we make, but if you want the best in noise attenuation, quality materials, and precision craftsmanship, it’s a genuine heavy hitter. The SOCOM65-Ti meet and exceed military sniper rifle suppressor specifications. It performs best with bolt-action weapon systems and precision rifles and weighs a mere 11 ounces while maintaining our strictest durability standards. The SOCOM65-Ti’s internal venting technology evenly distributes thermodynamic gases, significantly reducing pressure impulse effects on the projectile as it clears the muzzle. Precision manufacturing tolerances, strict attention to bore concentricity, and suppressor alignment combine to provide the best titanium suppressor available for 6 mm, 6.5 Creedmoor, and .260 caliber rifles.

SOCOM556 MG SUPPRESSOR

- The extreme-duty SOCOM suppressor is designed for 5.56 mm machine guns.

- Thicker materials and more robust baffles provide combat-proven continuous-fire reliability.

- It is expertly engineered to reduce sound, back pressure, suppressed cyclic rate, and gas blowback.

Keep It To A Whisper. The SOCOM556-MG is a beast ready to devour, precisely engineered to operate with maximum reliability and minimal sound on fully automatic rifles. A version of our USSOCOM suppressor trial-winning SOCOM556-RC suppressor, its thicker Inconel alloy and stainless steel, and more robust baffles provide extreme durability in the most demanding combat conditions. Our superior gas-flow dynamics significantly reduce back pressure, cyclic rate, and gas blowback on the shooter while effectively attenuating sound, decreasing flash, and reducing dust signature. Like all SureFire® suppressors, the MG is test-fired to ensure minimal and consistent point of impact shift, virtually eliminating the need to re-zero the weapon regardless of the number of attach-detach cycles.

SOCOM556 MINI2 SUPPRESSOR

- The SureFire® Mini with maximum sound attenuation

- Optimized for 14.5-inch and longer barrels on 5.56 mm M4 variants

- Unprecedented performance for its size

Make Every Inch Count. When the going gets tight, an inch can mean the difference between efficiently engaging the enemy or getting caught in a vulnerable position. That’s why SureFire® created the SOCOM556-MINI2. It delivers performance levels similar to the model that assured SureFire® the victory in the demanding USSOCOM suppressor trials but a more compact package optimized for 14.5-inch and longer barrels. A mere 5 inches long, it places a premium on efficiency and maintains the quality synonymous with every SureFire® suppressor. The innovative internal baffling significantly decreases back pressure, cyclic rate, and gas blowback. The net result is a tremendous reduction in sound and dust signature with virtually undetectable first-round flash and minimal, consistent point-of-impact shift.

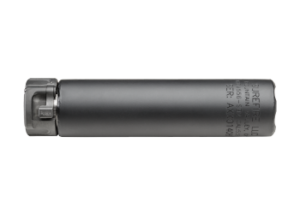

SOCOM556 SB2 SUPPRESSOR

- The best short-barrel 5.56 mm (.223 caliber) suppressor available

- Weighs a mere 17 ounces; minimal effect on weapon handling.

- Adds as little as 3.8 inches to overall weapon length

Use The Right Utensil. You don’t have to compromise on your suppressor’s performance or reliability just because your primary is a short-barreled rifle. The SOCOM556-SB2 is designed and engineered by the same dedicated team that produced the USSOCOM suppressor trial-winning SOCOM556-RC. The SB2’s larger bore diameter and innovative internal design deliver extremely low-back pressure and stealthy sound attenuation in a rugged suppressor optimized for rifle barrels of 10 inches or less. Its high-temperature alloys and stainless steel components are CNC laser-welded for strength and durability when shooting the SB2 in full-auto mode. It incorporates an innovative internal baffling that significantly decreases back pressure, cyclic rate, and gas blowback while delivering tremendous accuracy with a minimal and consistent point-of-impact shift. It’s the right tool for the job.

SOCOM556 RC2 SUPPRESSOR

- Our best-selling suppressor model

- It takes our SOCOM-winning design to the next level

- Extremely quiet, supremely accurate

Hold The Objective. Attach the SOCOM556-RC2 to any 5.56 mm weapon system with a minimum barrel length of 10 inches, and you will. The RC2 showcases the USSOCOM contract-winning know-how in cutting-edge suppressor design. It incorporates the latest in manufacturing techniques and materials to produce the most exceptional tool of its kind. Count on it to deliver the utmost in sound, flash, and dust signature reduction. The RC2 is precision-built of advanced Inconel alloys and stainless steel, and CNC laser-welded for uncompromising durability. The RC2 features unique internal baffling that reduces backpressure and sound, matching supreme accuracy with extreme quiet compared to an unsuppressed weapon. It’s the best overall suppressor in any environment.

SOCOM762-TI SUPPRESSOR

- The lightest 7.62 mm SureFire® suppressor available

- No-compromise performance, strength, and durability.

- Ideal for hunting and bolt-action precision rifle use

Lighten Up. The SOCOM762-Ti is simply the ultimate lightweight suppressor for 7.62 mm bolt-action rifles. Constructed of high-grade titanium, it weighs just 11 ounces, minimizing the impact on weapon handling characteristics. Although the material choices are lightweight, this suppressor does not compromise performance, strength, or durability standards. It meets and exceeds military sniper rifle suppressor specifications. The SOCOM762-Ti’s innovative venting technology evenly distributes thermodynamic gases, significantly reducing pressure impulse effects on the projectile as it clears the muzzle. It bears the SOCOM name, so you can be sure it delivers immense reductions in sound, flash, and dust signatures. Precise tolerances and strict attention to bore concentricity deliver exceptional alignment, resulting in a suppressor that maximizes accuracy and minimizes the point-of-impact shift. It may be light, but its impact is undeniable.

SOCOM300-SPS SUPPRESSOR

- The quietest SureFire® suppressor ever designed.

- Optimized for .300 BLK/Whisper (7.62×35) subsonic and supersonic ammo

- Engineered for extreme durability

Get Ready For The Blackout. The SureFire® SOCOM300-SPS is the answer for .300 BLK/Whisper (7.62 x 35) subsonic and supersonic ammo users seeking superior sound attenuation levels from a precision-built suppressor. It’s also very capable of 5.56 mm and 300 WM applications. The SPS features highly specialized, V-shaped baffles that promote the utmost in sound suppression for subsonic ammunition while virtually eliminating first-round flash and dust signatures. Constructed of Inconel alloy and stainless steel and CNC laser-welded, it’s stealthy without sacrificing an ounce of strength. Go ahead. Make it rain.

SOCOM762 MG SUPPRESSOR

- Extreme-duty SOCOM suppressor designed specifically for 7.62 mm auto rifles

- Incorporates thicker Inconel/stainless steel alloy and more robust baffles than the SOCOM762-RC for combat-proven continuous-fire reliability

- Expertly engineered to reduce sound, back pressure, suppressed cyclic rate, and gas blowback.

Fire The FPF. Robust. Rugged. Reliable. That’s the SOCOM762-MG. Designed expressly for use with 7.62 mm machine guns; it’s the extreme-duty model among our stout line of SOCOM suppressors. We take the advanced suppressor technology developed for our USSOCOM endorsed SOCOM762-RC, then beef it up with heavier Inconel and stainless steel construction and more robust baffling to withstand continuous automatic fire without fail. Our internal venting lessens back pressure, reducing suppressed cyclic rate and gas blowback on the operator. Our proprietary improvements in gas-flow dynamics attenuate noise, reduce dust signature to an unprecedented degree and nearly eliminate the first-round flash. Like all SureFire® SOCOM Fast-Attach® models, the MG produces minimal, consistent shift in point of impact compared with the unsuppressed weapon regardless of the number of attach-detach cycles. Employ your machine guns without attracting unwanted attention.

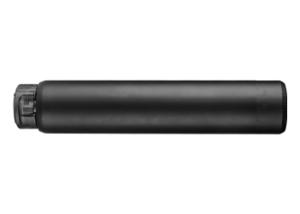

SOCOM762 RC2 SUPPRESSOR

- An improved version of the 7.62 mm suppressor chosen by USSOCOM

- Precisely engineered and constructed for combat superiority

- Supremely reliable sound, flash and dust attenuation

Stand On The Shoulders Of Giants. You want the best all-around suppressor for your .30 caliber platform. You’ve come to the right place. An improved version of the SOCOM762-RC trusted by elite military units worldwide, the SOCOM762-RC2 showcases years of expertise in the category. We have taken the tried-and-true design, refined it with advanced manufacturing processes, and tuned it for further dB reduction. Our advanced Inconel alloys and stainless steel are the best materials available, and they’re CNC laser-welded for the ultimate in strength and durability. Our meticulously designed internal baffling significantly reduces sound, flash, and dust signature with a minimal and consistent point-of-impact shift. Improve your position.

SOCOM762 MINI2 SUPPRESSOR

- The SureFire® Mini with maximum sound attenuation

- Optimized for 16-inch and longer barrels on 7.62 mm rifles

- Unprecedented performance for its size

Make Every Inch Count. The SureFire® SOCOM762-MINI2 delivers big performance levels in a small package optimized for 7.62 mm rifles equipped with 16-inch and longer barrels. It’s compact, measuring just 6.3 inches in length, but it places a premium on efficiency while maintaining the quality synonymous with the SureFire® suppressor that dominated the demanding USSOCOM suppressor trials. Our innovative internal baffling significantly decreases back pressure, cyclic rate, and gas blowback. The net result is a tremendous reduction in sound and dust signature with virtually undetectable first-round flash and minimal, consistent point-of-impact shift.

SOCOM338 TI SUPPRESSOR

- The quintessential titanium suppressor for the .338 Lapua rifle

- Precision tolerances deliver superior long-distance accuracy.

- Lightweight design meets combat-ready durability.

Keep Your Distance. The SOCOM338-Ti for .338 Lapua sniper rifles is a combat-ready suppressor hewn from high-grade titanium, one of the world’s lightest and most durable materials. Designed and built with extreme tolerances to ensure accuracy, it meets the demands of the most qualified precision sniper rifle shooters in the world. No one has tighter bore runout tolerances than we do, proving that this is the choice for the precision marksman. The SOCOM338 provides unsurpassed signature reduction, nominal and consistent shift in a weapon’s point of impact, and significantly reduced backpressure for consistent results. Expertly engineered, it gets you to where you want to go, no matter how far away it is.

SOCOM 50 SPS SUPPRESSOR

- Delivers up to 99 percent flash reduction to conceal the shooter’s location

- Significant sound and dust signature reduction

- Tight tolerances and bore concentricity result in excellent accuracy.

Tame The Beast. Highly specialized tools in the arsenal of our warfighters, .50 BMG rifles such as the TAC50 and M107 deliver a cannon-like report that’s as extreme as the weapons themselves. The new SureFire® SOCOM50 SPS tames these beasts with patented baffle technology that significantly attenuates sound, reduces flash by an amazing 99%, and virtually eliminates dust signature to mask the shooter’s position. The SOCOM50 SPS is machined to exacting tolerances and test fired to ensure sub – MOA accuracy. Precision manufacturing tolerances, attention to bore concentricity, and suppressor alignment produce the most accurate .50 – caliber suppressor available. The SOCOM50 SPS also incorporates an optimized integral muzzle brake to manage recoil for faster follow-up shots. Manufactured of stainless steel alloys in the U.S.A. and coated with a high-temperature Cerakote finish, the SOCOM50 SPS is durable enough to survive the harshest combat environments. The SOCOM50 SPS incorporates the innovative Fast – Attach® system that allows lightning-fast and rock-solid suppressor attachment without the use of tools. The SureFire® SOCOM50 SPS is the ultimate in suppressor performance for bolt-action and semi-automatic .50-caliber rifles.